Introduction

Cymbals are an integral part of drum sets and are known for producing distinct and vibrant sounds. If you’ve ever explored the world of drumming, you might have noticed that cymbals can come with a hefty price tag. This article aims to delve into the factors that contribute to the high cost of cymbals, providing insights into their craftsmanship, materials, manufacturing process, and market demand.

Craftsmanship and Materials

Crafting high-quality cymbals involves a meticulous process that requires skilled artisans. Master cymbal makers spend years honing their techniques, ensuring each cymbal is crafted to perfection. The materials used, such as bronze alloys, contribute to the overall quality and sound characteristics of the cymbal. These materials, often sourced from different regions worldwide, can be expensive, impacting the final price of the cymbal.

Cymbals are primarily made from bronze, an alloy of copper and tin, with the most common compositions being B8 (8% tin) and B20 (20% tin). The price of these raw materials can fluctuate, but it’s the ratio of tin to copper that significantly affects the cost. Higher tin content, as seen in B20 alloys, is more challenging to work with and requires more processing, leading to higher prices. Despite the raw material cost being relatively low, the extensive work required to achieve the desired sound quality adds to the expense.

Manufacturing Process

The creation of cymbals is a labor-intensive process that requires a high level of skill and precision. Each cymbal undergoes several stages of production, including casting, rolling, shaping, hammering, and lathing. The process can take up to a week for traditional methods, significantly contributing to the final cost. Modern manufacturing methods, such as sheet metal stamping, can produce cymbals in a day, but the labor costs involved in traditional methods are a primary factor driving up prices.

Market Demand

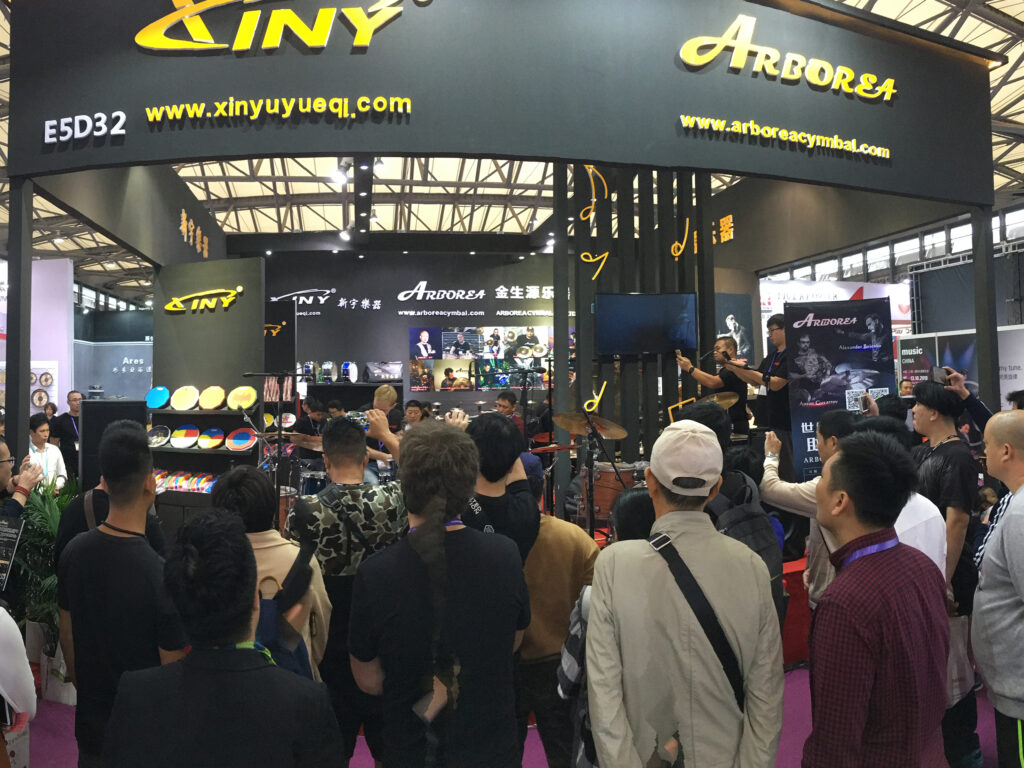

The demand for cymbals, especially those from well-established brands, significantly affects their price. Renowned drummers and musicians endorse specific cymbal brands, creating a buzz around their products. This endorsement and the desire to replicate the sound of influential artists contribute to the demand and, consequently, the price of cymbals.

Quality and Durability

Expensive cymbals often possess superior quality and durability. Manufacturers invest in research and development to enhance the longevity of their products. Higher-priced cymbals are designed to withstand the rigors of extensive playing and provide consistent sound quality over time. These factors contribute to the higher cost but also ensure that the investment in a cymbal is worthwhile.

Size and Thickness

The size and thickness of a cymbal also influence its price. Larger and thicker cymbals require more material and are often used in professional settings, leading to higher prices. The weight and thickness affect the sound quality and durability, with heavier cymbals typically producing a louder sound and being more resilient to cracking.

Handmade vs. Machine-made

Handmade cymbals, which are often considered superior in terms of sound quality, are more expensive due to the labor-intensive process involved in their creation. Each cymbal is unique, with irregularities introduced by hand hammering contributing to its complex sound. Machine-made cymbals, while more consistent and less costly to produce, may lack the unique character of their handmade counterparts.

Branding and Endorsements

Branding plays a significant role in the pricing of cymbals. Well-established brands with a long history and reputation tend to command higher prices due to their market standing. Additionally, endorsements from popular drummers and musicians elevate the value and desirability of specific cymbal models, further driving up their cost.

The reputation of a cymbal brand plays a crucial role in its pricing. Established brands like Zildjian, Sabian, Meinl, and Paiste have a long history of producing high-quality cymbals, which commands a premium price. These brands invest significantly in research and development to innovate and maintain their market position, which is reflected in their pricing.

Research and Development

Innovation and continuous improvement are essential aspects of the cymbal industry. Manufacturers invest in research and development to create new cymbal designs, materials, and manufacturing techniques. These advancements require financial resources, which are reflected in the pricing of newer and more innovative cymbals.

Specialized Cymbals

Cymbals designed for specific genres or playing styles, such as jazz, rock, or orchestral music, often come with a higher price tag. These specialized cymbals are tailored to meet theunique demands of certain musical styles, requiring extensive research and development. The customization and specialization contribute to the increased cost of these cymbals.

Variety and Customization

The availability of a wide range of cymbal options and the ability to customize them to individual preferences can contribute to their higher prices. Different sizes, weights, finishes, and sound characteristics offer drummers the opportunity to find the perfect cymbal that suits their playing style. The additional effort and resources required to produce and offer such variety and customization options affect the overall cost.

Innovation and Uniqueness

Innovation and uniqueness in cymbal design and sound creation can drive up their prices. Manufacturers constantly strive to introduce new and distinct sounds to cater to evolving musical trends. This pursuit of innovation, coupled with the cost of developing and refining new cymbal models, contributes to the higher price range.

Market Competition

Competition within the cymbal industry plays a significant role in pricing. Established brands with a loyal customer base and a reputation for quality can set higher prices. However, newer brands may offer competitive pricing to gain market share. The interplay between market competition and brand reputation influences the pricing strategies of cymbal manufacturers.

Distribution and Retail Margins

The distribution and retail process also impacts the price of cymbals. Distributors and retailers often add their margins to cover operating costs, marketing, and sales efforts. These additional costs are passed on to the consumer, contributing to the overall price of cymbals.

Maintenance and Lifespan

Cymbals, like any musical instrument, require proper maintenance to ensure their longevity and optimal performance. The cost of maintaining cymbals, including cleaning products, protective cases, and regular upkeep, can add to their overall cost. Additionally, high-quality cymbals often have a longer lifespan, reducing the need for frequent replacements and justifying their higher price.

Investment Value

Some cymbals hold investment value due to their rarity, historical significance, or association with legendary drummers. These collectible cymbals can appreciate in value over time, making them desirable for collectors and enthusiasts. The investment potential adds to their price, making them more expensive than standard cymbals.

Conclusion

In conclusion, the high cost of cymbals can be attributed to various factors. Craftsmanship, materials, manufacturing processes, market demand, branding, research and development, customization, innovation, market competition, distribution, maintenance, and investment value all play a role in determining the price of cymbals. As drummers and musicians seek the perfect sound and quality, the investment in expensive cymbals becomes a worthwhile endeavor.