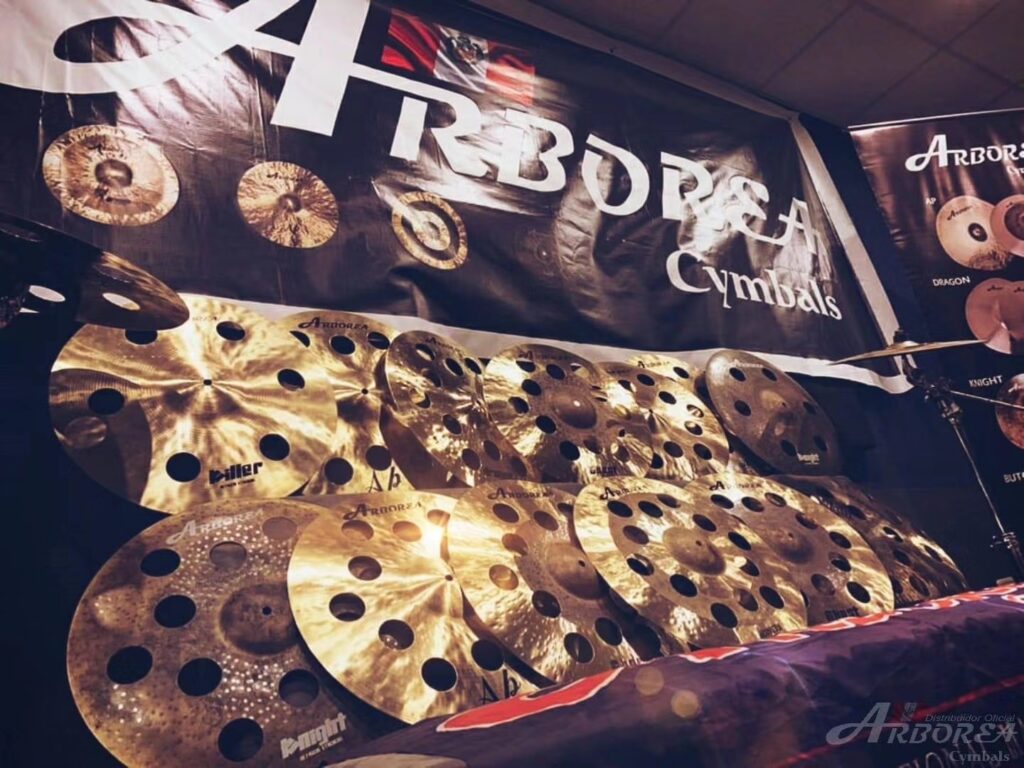

Step into the world of resonating Eastern melodies with our handcrafted Sun Wind Gong. A stunning blend of tradition and artistry, each strike on the gong radiates a sound as brilliant as the sun itself.

| Material: | 80%copper+20%Tin |

|---|---|

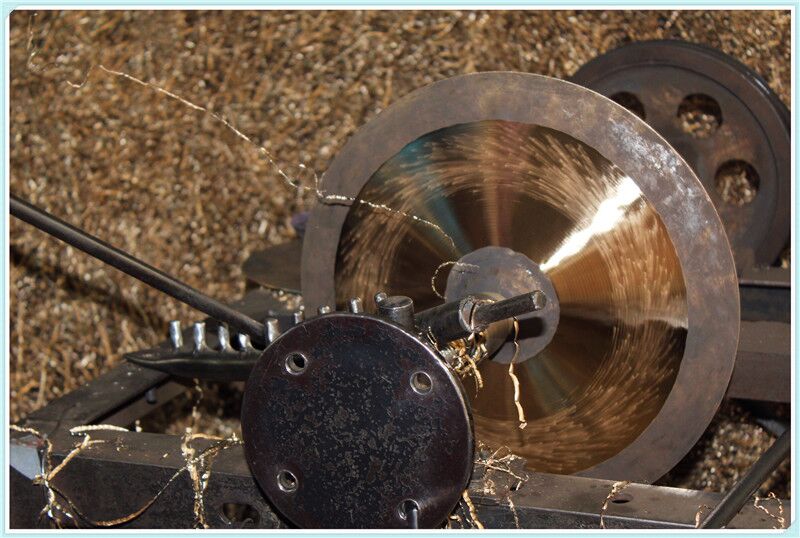

| Process: | 100% hand made |

| Color: | bronze and black |

| Pack: | carton |

| Diameter | 14 inch, 16 inch, 18 inch, 20 inch, 22 inch, 24 inch, 26 inch, 28 inch, 30 inch, 32 inch, 34 inch, 36 inch, 38 inch, 40 inch, 42 inch, 44 inch, 48 inch, 52 inch |

$62.00 – $3,630.00

Our Sun Wind Gong stands as a testament to our commitment to preserving ancient Eastern musical traditions while showcasing impeccable craftsmanship. Crafted by skilled artisans, each Sun Wind Gong is more than a mere musical instrument—it embodies a living piece of history that echoes with every strike. The Sun Wind Gong is meticulously fashioned to produce a unique, radiant sound. Its resonant tones echo the warmth and brilliance of the sun, creating an unparalleled auditory experience that envelops spaces with a comforting, luminous aura. In terms of aesthetics, the Sun Wind Gong is a masterpiece. Its surface, adorned with an intricate sun motif, symbolizes vitality, warmth, and the revitalizing essence of the sun. This fusion of visual appeal and musicality makes our Sun Wind Gong a captivating addition to any musical ensemble or artistic collection. Recognizing the significance of personalization, we offer customization options for our Sun Wind Gong. Clients can infuse their distinct patterns or styles, transforming this already exceptional musical instrument into a personalized artifact that resonates with their unique tastes and personality. Investing in our Sun Wind Gong transcends mere musical acquisition; it’s an investment in a timeless piece of art, a catalyst for conversations, and a cultural heritage that spans generations. Immerse yourself in the captivating blend of history, craftsmanship, and individuality with our Sun Wind Gong, and let it infuse your space with the echoes of tradition and the radiant warmth of the sun.

Fanjia Vililage, Shuizhai Town, Zhangqiu City, Shandong, China

We will contact you within 1 working day, please pay attention to the email