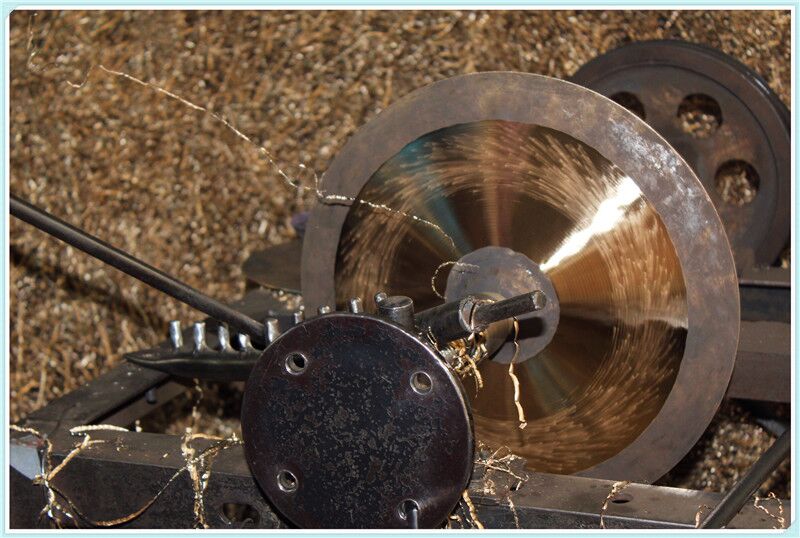

New Alloy Wind Gong, a revolutionary musical instrument that blends cutting-edge technology with timeless craftsmanship. Meticulously crafted by skilled artisans, each New Alloy Wind Gong is a testament to precision engineering and innovation. The gong’s unique alloy composition produces a distinct and resonant sound, offering a modern twist on traditional craftsmanship.

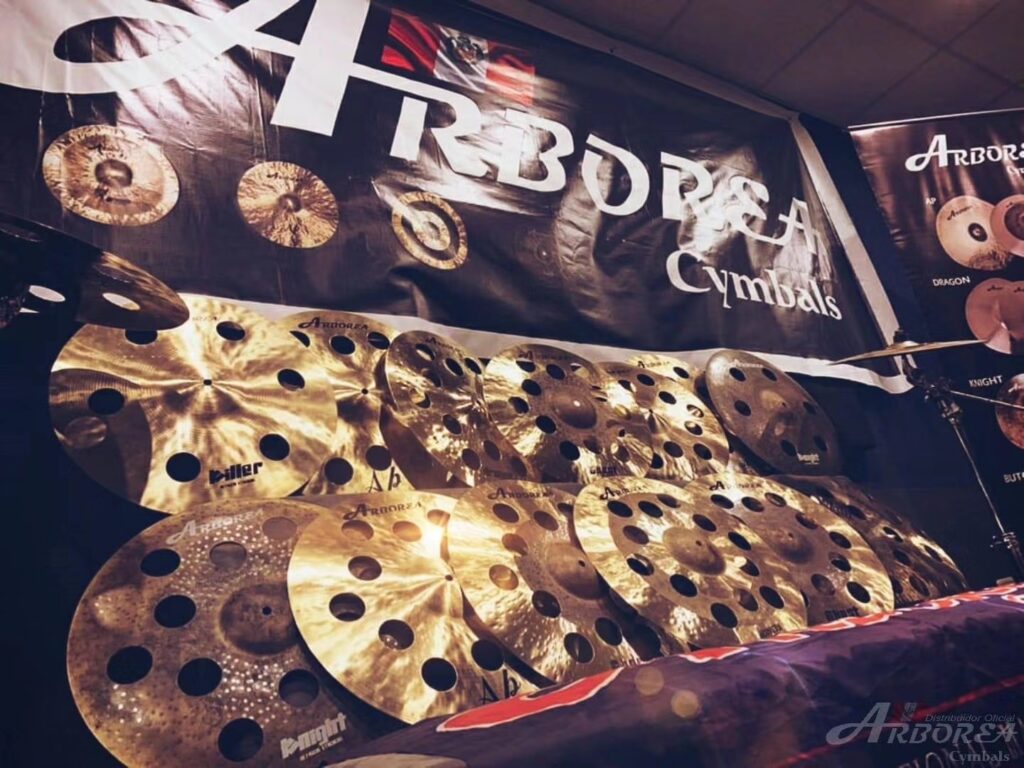

Designed with both aesthetics and performance in mind, the New Alloy Wind Gong features a sleek and contemporary look. Its artisan-crafted designs showcase a perfect balance of sophistication and functionality, making it a stunning addition to any musical setup or decor.

| Material: | Alloy |

|---|---|

| Color: | Red |

| Pack: | carton |

| Diameter | 16 inch, 18 inch, 20 inch, 22 inch, 24 inch, 26 inch, 28 inch, 30 inch, 32 inch, 34 inch, 36 inch, 38 inch, 40 inch, 6 inch, 8 inch |

$146.00 – $670.00

The New Alloy Wind Gong, a testament to delicate artisanship and ancestral wisdom, stands as a symbol of our unwavering commitment to authenticity and the preservation of historical narratives. Forged by the skilled hands of expert craftsmen, each New Alloy Wind Gong is a captivating journey through time, providing a tangible link to the rich tapestry of our past. This unique musical instrument transcends its role as a sound device; it becomes a channel through which our cultural heritage resonates.

Crafted with precision, passion, and profound respect for tradition, each New Alloy Wind Gong offers a distinctive auditory experience. The resonating sound, akin to a gentle breeze, mirrors the tranquil melodies found in nature’s quietest moments. This harmonious echo transforms any space into a serene Eastern landscape, creating a comforting sonic background for your surroundings.

Yet, the beauty of the New Alloy Wind Gong extends beyond its enchanting sound. The visual elegance of each instrument is equally captivating, showcasing unique, artisan-crafted designs that embody an ancient art form passed down through generations. The intricate patterns and finishes reflect our unwavering dedication to quality and detail, resulting in a breathtaking piece of decor that seamlessly blends functionality with aesthetics.

Recognizing the significance of personal touch, we proudly offer customizable designs for our New Alloy Wind Gongs. Whether it’s a distinct pattern or a unique style, we invite you to personalize your gong, transforming it from a mere musical instrument into a cherished personal artifact. Each New Alloy Wind Gong becomes an echo of its owner’s personality, a one-of-a-kind masterpiece that complements individual taste and style.

With our New Alloy Wind Gong, you’re not just acquiring a musical instrument; you’re investing in a timeless piece of art, an enduring conversation piece, and a legacy to pass down through generations. Each gong tells a story – of its creation, its creator, and its owner – intertwining narratives that build over time. Embrace the harmony of expert craftsmanship, historical richness, and soulful sound with our New Alloy Wind Gong. Step into a resonating symphony of tradition as you become part of an ongoing legacy that spans centuries.

Fanjia Vililage, Shuizhai Town, Zhangqiu City, Shandong, China

We will contact you within 1 working day, please pay attention to the email