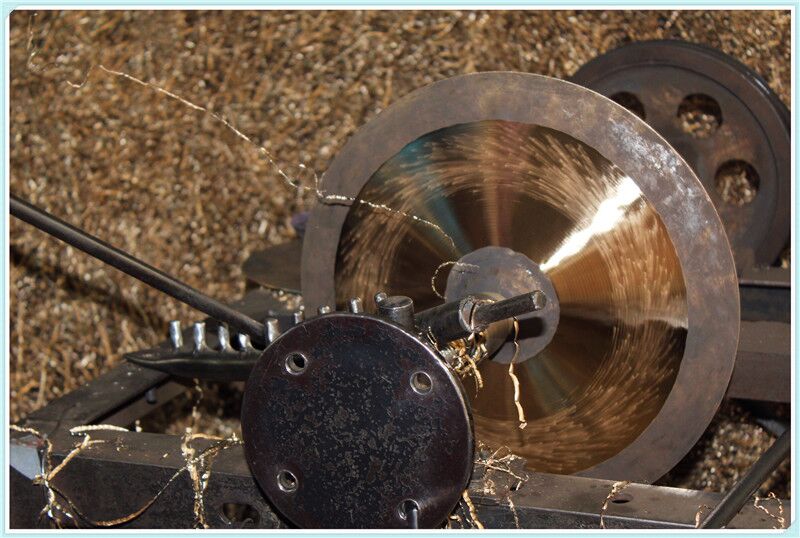

The New Alloy Wind Gong is a groundbreaking musical instrument that seamlessly integrates advanced technology with traditional craftsmanship. Each gong is meticulously crafted by skilled artisans, serving as a testament to both precision engineering and innovation.This gong’s unique alloy composition generates a distinct and resonant sound, providing a modern twist on classic designs.Design and Aesthetics

Overall, the New Alloy Wind Gong stands out as a stunning addition to both musical collections and decorative spaces.

| Material: | Alloy |

|---|---|

| Color: | Green |

| Pack: | carton |

| Diameter | 16 inch, 18 inch, 20 inch, 22 inch, 24 inch, 26 inch, 28 inch, 30 inch, 32 inch, 34 inch, 36 inch, 38 inch, 40 inch, 6 inch, 8 inch |

$146.00 – $670.00

The New Alloy Wind Gong, a representation of exquisite craftsmanship and deep-rooted heritage, symbolizes our steadfast dedication to authenticity and the safeguarding of historical narratives. Handcrafted by expert artisans, each gong offers a mesmerizing journey through time, creating a tangible connection to the intricate tapestry of our past. This unique musical instrument transcends its function as a sound device; it serves as a conduit for our cultural legacy.Craftsmanship and Sound

Visual Elegance

Customization Options

With the New Alloy Wind Gong, you are not merely acquiring an instrument; you are investing in a timeless work of art, an enduring conversation starter, and a legacy to be cherished across generations. Each gong tells its own story—of creation, craftsmanship, and ownership—intertwining narratives that evolve over time. Embrace the harmony of expert artisanship, historical depth, and soulful sound with the New Alloy Wind Gong. Step into a resonating symphony of tradition as you become part of an ongoing legacy that spans centuries.

Fanjia Vililage, Shuizhai Town, Zhangqiu City, Shandong, China

We will contact you within 1 working day, please pay attention to the email