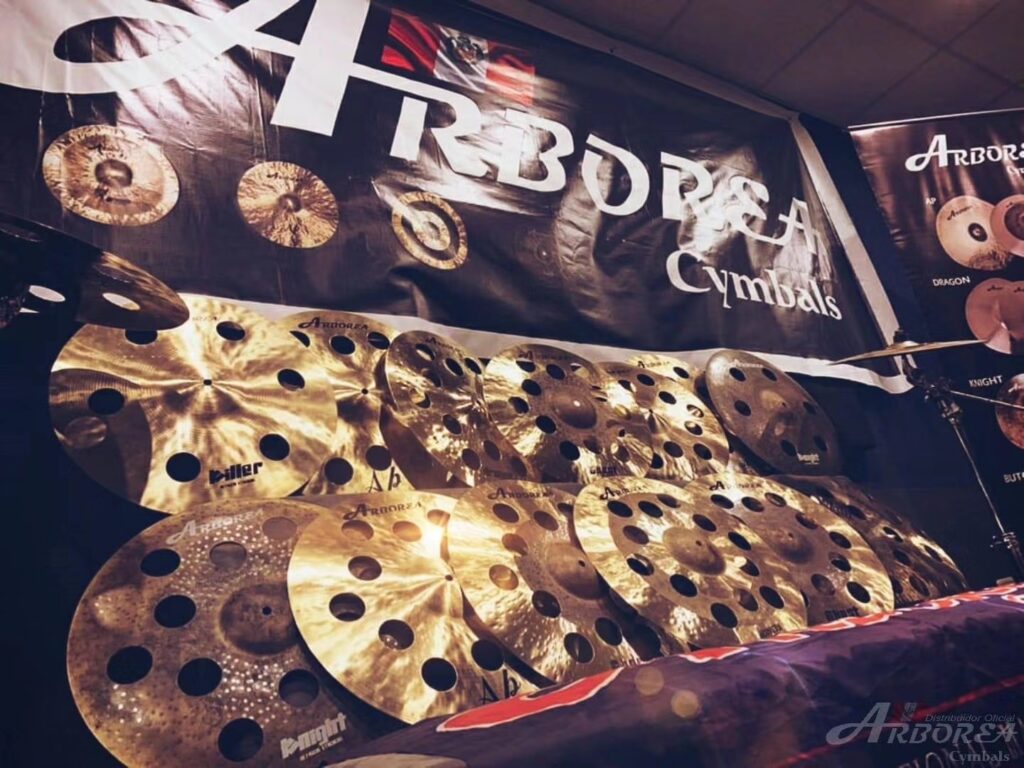

Experience the pinnacle of sound quality with the Arborea FH Series Cymbal. Immerse yourself in a world of exceptional craftsmanship and musical brilliance. Meticulously crafted with precision and artistry, this cymbal delivers unparalleled clarity, rich tones, and a captivating musical experience that will elevate your performance to new heights.

| Material: | B20 |

|---|---|

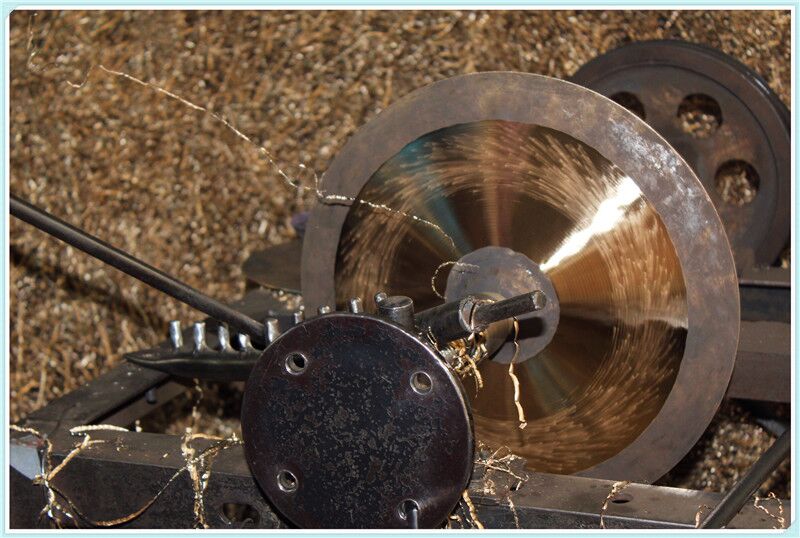

| Process: | 100% hand made |

| Color: | original |

| Pack: | carton |

| Diameter | 10 inch, 12 inch, 13 inch, 14 inch, 14''HH+16''C+20''R+CYMBAL BAG, 14'HH+16''C+18''C+20''R+CYMBAL BAG, 16 inch, 18 inch, 20 inch, 8 inch |

| Types | A set, CRASH, CRASH RIDE, HIHAT, RIDE, SPLASH |

$12.00 – $189.00

Enter a realm of sonic excellence with the Arborea FH Series Cymbal. Meticulously handcrafted with meticulous attention to detail and a touch of artistry, this cymbal embodies the essence of superior craftsmanship and musical brilliance. The Arborea FH Series Cymbal exudes a captivating presence, offering a rich and expressive sound that captivates listeners. Crafted with precision and utilizing premium materials, it produces a clarity and tonal richness that brings your playing to life. From explosive crashes that resonate with power to nuanced ride patterns and enchanting accents, the Arborea FH Series Cymbal showcases exceptional versatility. Its responsive nature and articulate response allow drummers to explore a wide range of musical styles, infusing their performances with remarkable expression. Whether you’re unleashing energetic fills or crafting intricate rhythmic patterns, this cymbal responds with unparalleled clarity and a mesmerizing tonal range. The Arborea FH Series Cymbal boasts a harmonious balance of projection and tonal complexity. Its meticulously crafted design and precise lathing create a symphony of rich and vibrant tonal nuances. Each strike reveals layers of depth and character, elevating your playing to new heights and captivating both the audience and your musical peers. Unleash your creativity and embark on a musical odyssey with the Arborea FH Series Cymbal. Whether you’re a seasoned performer or an aspiring musician, this cymbal empowers you to explore new dimensions of sonic expression. Elevate your performance and let the Arborea FH Series Cymbal become your trusted companion on every stage, studio session, and musical endeavor. Experience the captivating allure of the Arborea FH Series Cymbal. Let its exceptional sound quality redefine your musical journey and inspire you to create unforgettable moments. Unleash your passion and let the Arborea FH Series Cymbal be the catalyst for your sonic exploration and artistic growth.

Fanjia Vililage, Shuizhai Town, Zhangqiu City, Shandong, China

We will contact you within 1 working day, please pay attention to the email