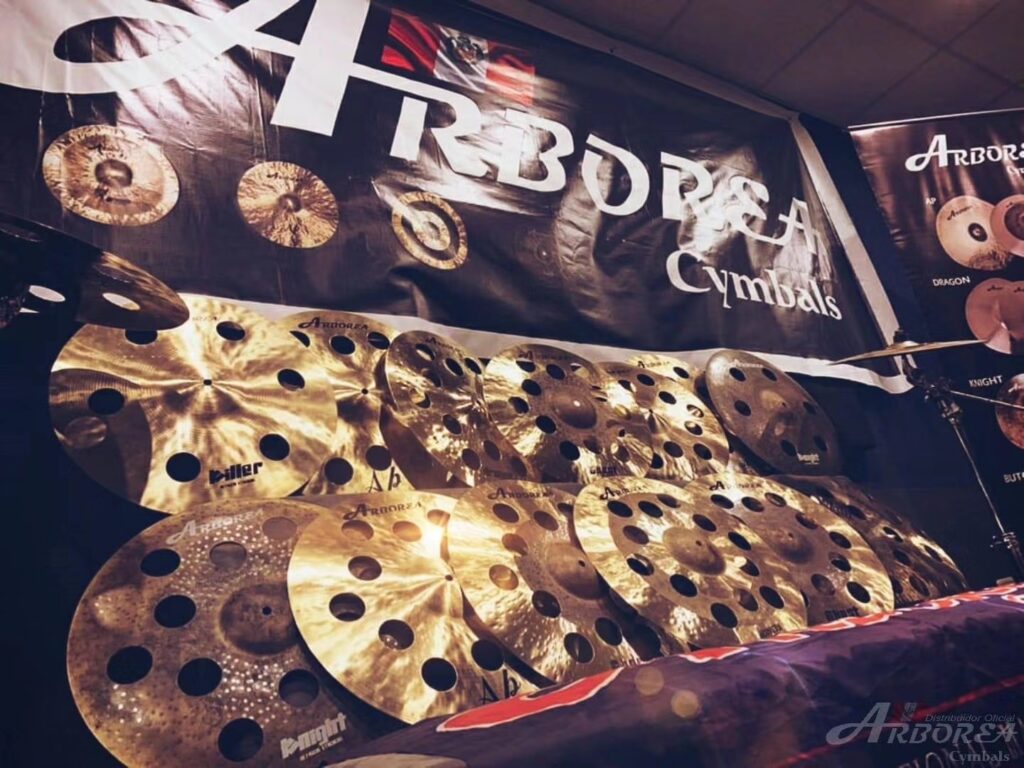

Embrace the cutting-edge of cymbal technology with our Arborea Edge Series Cymbal. Precision-engineered for superior sound and durability, it’s the perfect companion for musicians who dare to push the boundaries.

| Material: | B20 |

|---|---|

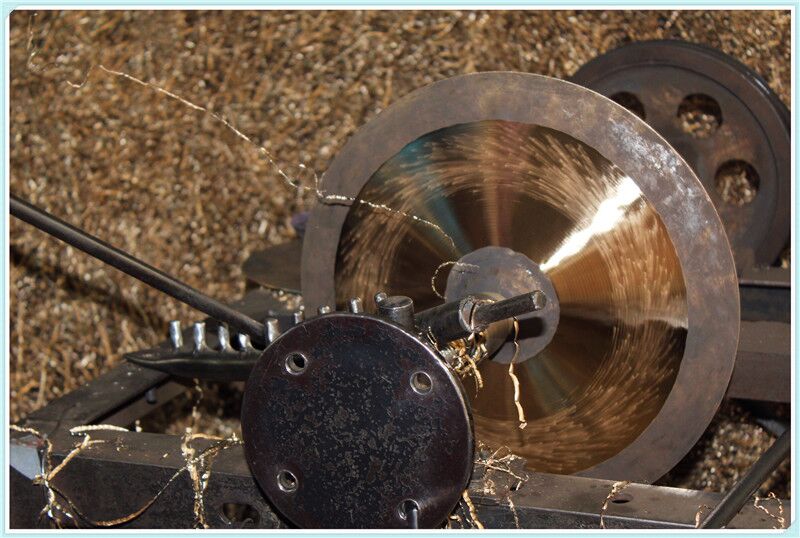

| Process: | 100% hand made |

| Color: | original |

| Pack: | carton |

| Diameter | 10 inch, 11 inch, 12 inch, 13 inch, 14 inch, 14'HH+16''C+18''C+20''R+CYMBAL BAG, 15 inch, 16 inch, 17 inch, 18 inch, 19 inch, 20 inch, 21 inch, 22 inch, 23 inch, 24 inch, 6 inch, 7 inch, 8 inch, 9 inch |

| Types | 12 AIR OZONE EFFECTS, A set, BELL, CHINA CYMBAL, CRASH, HEAVY RIDE, HIHAT, MEDIUM CRASH, MEDIUM RIDE, O-ZONE CYMBAL, OZ12 EFFECTS CHINA, RIDE, ROCKTA GONG, SPLASH, TAMBO RINE O-ZONE |

$24.00 – $575.00

Our Arborea Edge Series Cymbal embodies our commitment to pushing the limits of musical craftsmanship. Each cymbal is crafted with precision, delivering a balance of robust durability and highly sensitive responsiveness, making it a key part of your percussion setup. The Arborea Edge Series Cymbal is designed for musicians of all levels, offering a versatile range of sounds. Its sturdy build and balanced weight provide exceptional control, allowing you to explore a wide spectrum of tones. Whether you’re seeking the bright shimmer of a ride or the deep crash of an accent, the Edge Series Cymbal enables you to discover the full potential of your music. Visually, the Arborea Edge Series Cymbal is a standout. Its uniquely engineered design, combined with a sleek, polished finish, creates an aesthetic that is both striking and functional. The high-quality materials used in its construction assure its longevity, making it a reliable and stylish addition to any drum kit. Recognizing the significance of individual expression, we offer customization options for our Arborea Edge Series Cymbal. Whether you’re seeking a specific weight, a unique finish, or personalized engravings, you can modify this instrument to suit your unique needs and tastes. Investing in our Arborea Edge Series Cymbal is more than just acquiring a musical instrument—it’s about expanding your musical capabilities, enhancing the visual appeal of your drum kit, and possessing a piece of craftsmanship that will last. Experience the full breadth and depth of your music’s potential with our Arborea Edge Series Cymbal.

Fanjia Vililage, Shuizhai Town, Zhangqiu City, Shandong, China

We will contact you within 1 working day, please pay attention to the email