Understanding cymbal alloys is fundamental to making informed manufacturing decisions that impact product quality, market positioning, and business success. As cymbal manufacturers with extensive experience serving global OEM partners, we’ve witnessed how alloy selection affects every aspect of production—from acoustic performance and manufacturing costs to market competitiveness and brand differentiation.

The two primary bronze alloys dominating professional cymbal manufacturing, B20 and B8, each offer distinct characteristics that serve different market segments and manufacturing objectives. B20 bronze contains 80% copper and 20% tin, creating complex harmonic structures that define professional-grade instruments. B8 bronze, with 92% copper and 8% tin, provides bright, focused tonal characteristics while maintaining cost-effective production economics.

B20 Bronze: The Premium Performance Standard

B20 bronze represents the pinnacle of cymbal alloy technology, delivering the acoustic complexity and musical responsiveness that serious musicians demand. The high tin content creates rich overtone development that evolves dynamically throughout each cymbal’s sustain period. When musicians strike a B20 cymbal, they experience immediate responsiveness to subtle playing variations, with harmonic content that changes based on strike location, stick angle, and dynamic force.

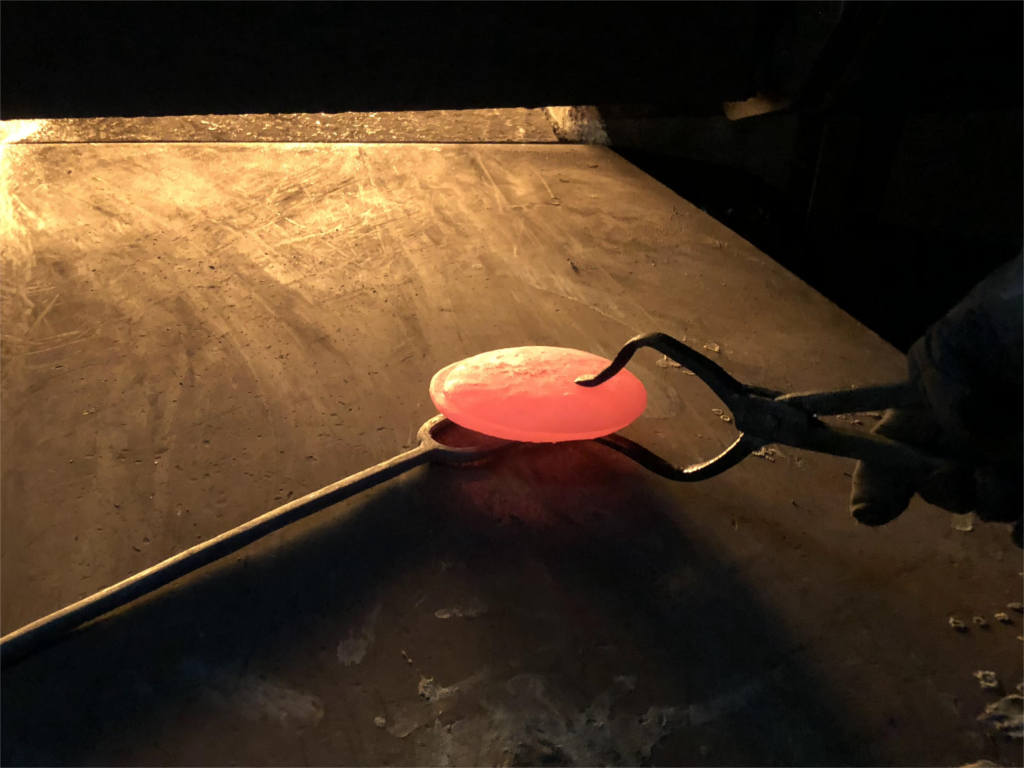

This acoustic sophistication comes with manufacturing complexity that OEM partners must consider carefully. B20 bronze requires specialized processing techniques that demand experienced craftsmen and extended production times. The alloy’s unique characteristics respond differently to hammering, lathing, and heat treatment compared to lower-tin bronzes, requiring manufacturers to invest in both equipment and expertise.

However, these manufacturing challenges translate directly into market advantages. B20 cymbals command premium pricing in professional markets, from jazz clubs and recording studios to symphony halls and conservatories. Musicians recognize the superior harmonic complexity and dynamic sensitivity that B20 provides, making these cymbals essential for serious musical applications where subtle expression and acoustic authenticity matter most.

The economics of B20 production favor OEM manufacturers targeting premium market segments. While raw material costs are higher due to increased tin content, the resulting products support pricing strategies that more than compensate for the additional manufacturing investment. Professional drummers and institutions regularly invest in B20 cymbals as long-term purchases, understanding that these instruments maintain their acoustic properties and market value over decades of use.

B8 Bronze: Balancing Performance with Efficiency

B8 bronze offers OEM manufacturers an optimal balance between professional-grade performance and manufacturing efficiency. The 8% tin content creates bright, cutting tonal characteristics that excel in high-volume musical environments while maintaining production economics that support competitive pricing strategies.

Musicians appreciate B8 cymbals for their consistent, reliable performance across various musical styles. The focused frequency response cuts through amplified band arrangements effectively, while the reduced harmonic complexity provides clear, defined sounds that work well in recording environments. This consistency extends to manufacturing, where B8’s predictable behavior enables reliable production schedules and quality outcomes.

From a manufacturing perspective, B8 bronze simplifies production processes significantly compared to B20. The alloy responds consistently to standard forming techniques, requires less specialized equipment, and allows for higher production throughput. Quality control becomes more straightforward as B8 maintains consistent characteristics across production runs, reducing testing complexity and ensuring reliable performance standards.

The market applications for B8 cymbals span from educational institutions seeking quality instruments at accessible price points to professional musicians requiring reliable performance tools. This versatility makes B8 an excellent choice for OEM manufacturers developing product lines that serve multiple market segments simultaneously.

Manufacturing Considerations for OEM Success

Successful OEM cymbal manufacturing requires understanding how alloy characteristics translate into production requirements and market opportunities. B20 production demands investment in specialized equipment, skilled craftsmen, and comprehensive quality control systems. The manufacturing process typically takes longer, with multiple stages of hammering, heat treatment, and finishing that require expert oversight.

B8 production offers greater manufacturing flexibility with standardized processes that deliver consistent results. The alloy’s predictable behavior enables efficient production scheduling and resource allocation, making it ideal for OEM manufacturers prioritizing volume production and competitive pricing.

Quality assurance protocols differ significantly between the two alloys. B20 requires intensive testing to ensure the complex harmonic characteristics meet professional standards, while B8 benefits from streamlined testing procedures that focus on consistency and reliability. Both approaches demand rigorous attention to detail, but the testing complexity varies considerably.

Understanding these manufacturing differences helps OEM partners make informed decisions about production capabilities, quality systems, and market positioning strategies. Success requires aligning alloy choice with manufacturing strengths and market objectives.

Strategic Market Positioning

B20 and B8 alloys serve distinctly different market positioning strategies that OEM manufacturers should consider carefully. B20 enables premium market entry with products that compete directly against established professional brands. The superior acoustic characteristics justify higher pricing while building brand credibility among serious musicians and industry professionals.

B8 supports competitive market penetration strategies where value proposition becomes the primary differentiator. The combination of professional-grade performance with efficient manufacturing economics enables aggressive pricing while maintaining healthy profit margins.

Regional market considerations also influence alloy selection significantly. Emerging markets often prioritize cost-effectiveness over acoustic complexity, making B8 an excellent choice for international expansion. Established markets with sophisticated musical communities frequently demand the acoustic sophistication that only B20 can provide.

Export opportunities vary considerably between the two alloys. B20 cymbals compete effectively in international premium markets where acoustic quality commands respect regardless of brand origin. B8 cymbals excel in volume export markets where competitive pricing combined with reliable quality creates compelling value propositions.

Investment Analysis and Return Expectations

The financial implications of alloy selection extend far beyond raw material costs to encompass equipment investment, training requirements, production efficiency, and market pricing potential. B20 production requires substantial upfront investment in specialized equipment and skilled personnel, but this investment supports premium pricing strategies that can generate superior long-term returns.

B8 manufacturing offers faster return on investment through higher production volumes and more predictable cash flows. The standardized production processes enable efficient capacity utilization while maintaining quality standards that support stable market demand.

Market development timelines also differ significantly between the alloys. B20 products often require longer market development periods as musicians evaluate acoustic characteristics and build confidence in new brands. B8 products can achieve market acceptance more quickly, particularly when positioned as value alternatives to established premium brands.

Quality Systems and Brand Protection

Implementing appropriate quality systems becomes crucial for protecting brand reputation and ensuring customer satisfaction regardless of alloy choice. B20 production demands comprehensive acoustic testing protocols that validate harmonic complexity and dynamic responsiveness. These testing procedures require specialized equipment and trained personnel capable of evaluating subtle acoustic characteristics.

B8 quality systems focus on consistency and reliability testing that ensures predictable performance across production runs. While less complex than B20 testing, these procedures remain essential for maintaining customer confidence and market competitiveness.

Brand protection strategies must align with alloy characteristics and market positioning. B20 brands require careful cultivation of professional relationships and industry credibility, while B8 brands benefit from volume distribution and competitive pricing strategies that build market share rapidly.

Future Trends and Innovation Opportunities

The cymbal industry continues evolving as manufacturing technology advances and musical styles develop. Computer-aided design and analysis tools enable more precise alloy optimization and quality control, while advanced manufacturing techniques improve consistency and efficiency for both B20 and B8 production.

Sustainability considerations increasingly influence purchasing decisions, creating opportunities for manufacturers who can demonstrate environmental responsibility while maintaining acoustic quality. Both alloys offer opportunities for sustainable manufacturing practices through improved efficiency and waste reduction.

Market globalization continues expanding opportunities for OEM manufacturers who understand how alloy characteristics align with regional preferences and economic conditions. Success requires balancing acoustic authenticity with market accessibility, whether through B20’s premium positioning or B8’s competitive value proposition.

Making the Strategic Choice

Choosing between B20 and B8 alloys requires careful analysis of market objectives, manufacturing capabilities, and long-term business strategy. B20 offers superior acoustic characteristics that justify premium pricing but demands significant manufacturing investment and expertise. B8 provides excellent balance between performance and efficiency, enabling competitive positioning while maintaining professional-grade quality.

Our commitment to OEM partner success includes providing comprehensive technical support, quality assurance guidance, and market insights that ensure optimal alloy selection for specific business objectives. Whether pursuing premium market leadership through B20 or competitive market penetration with B8, we offer the expertise and manufacturing excellence that drives long-term success.

The future belongs to OEM manufacturers who understand how alloy characteristics translate into market advantages and manufacturing efficiency. Through strategic alloy selection, comprehensive quality systems, and market-focused development, we help our partners build sustainable competitive advantages that generate exceptional returns in the global cymbal market.

Contact our OEM development team to discuss how B20 and B8 alloy strategies can support your specific market objectives and manufacturing requirements. Together, we can develop comprehensive approaches that maximize your competitive position and ensure lasting success in your target markets.