The quality of a cymbal is determined by various factors throughout its manufacturing process and design. Understanding these elements can help drummers and percussionists make informed decisions when selecting cymbals for their kit.Material CompositionThe alloy used in cymbal production significantly impacts its sound and durability:

- B20 bronze (80% copper, 20% tin) is commonly used in high-end cymbals for its rich, complex tones.

- B8 bronze (92% copper, 8% tin) is often found in mid-range cymbals, producing brighter sounds.

- Other alloys, such as brass or nickel-silver, are sometimes used for specific tonal characteristics.

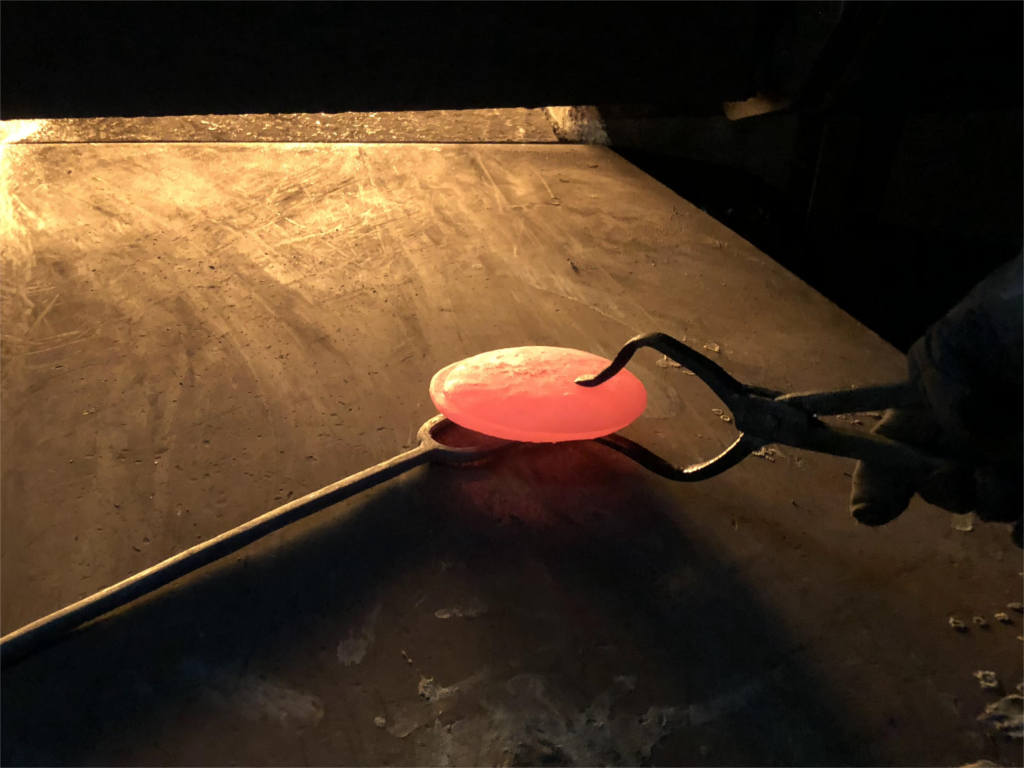

Manufacturing ProcessThe method of cymbal creation greatly influences its quality:

- Cast cymbals: Individually poured from molten metal, resulting in unique sonic characteristics and generally higher quality.

- Sheet cymbals: Stamped from large metal sheets, offering more consistency but potentially less complexity in sound.

Shaping and HammeringThe cymbal’s shape and hammering pattern affect its tonal properties:

- Profile (taper): A higher taper from bell to edge creates higher frequencies and faster sound.

- Weight: Heavier cymbals produce higher pitches, while lighter ones have lower pitches.

- Hammering technique: Hand-hammering can create more complex overtones compared to machine hammering.

LathingThe lathing process impacts the cymbal’s timbre and sustain:

- Fully lathed cymbals tend to have a more traditional, balanced sound.

- Partially lathed or unlathed cymbals often have a darker, more complex tone.

- The depth and pattern of lathing grooves can affect the cymbal’s overtones and decay.

Size and ThicknessThese physical attributes significantly influence the cymbal’s sound:

- Larger cymbals generally produce lower pitches and have longer sustain.

- Thinner cymbals tend to be more responsive and have a faster decay, while thicker ones have more volume and sustain.

FinishingThe cymbal’s surface treatment can subtly alter its sound:

- Brilliant finish: Achieved through polishing, slightly reducing high-end frequencies.

- Natural finish: Retains more of the cymbal’s original tonal characteristics.

- Special coatings: Can be used to simulate aging or create unique tonal effects.

Quality ControlThe manufacturer’s commitment to quality assurance plays a crucial role:

- Consistency in production ensures that cymbals of the same model sound similar.

- Hand-testing each cymbal against a master reference cymbal helps maintain high standards.

Playing Technique and EnvironmentWhile not manufacturing factors, these elements affect perceived quality:

- Proper playing technique can bring out the best in a cymbal’s sound.

- The acoustic environment (room size, materials) can significantly impact how a cymbal sounds.

Understanding these factors can help drummers choose cymbals that best suit their playing style and musical needs. It’s important to note that personal preference plays a significant role in cymbal selection, as the “best” cymbal is ultimately the one that sounds right to the individual player and fits well within their musical context.