The transformation of raw bronze into a resonant, musical cymbal represents one of the most fascinating journeys in instrument manufacturing. As experienced cymbal craftsmen, we understand that every step in this intricate process—from selecting premium alloys to the final quality inspection—directly impacts the instrument’s tonal character, durability, and musical expression. This comprehensive exploration reveals the secrets behind cymbal manufacturing and the artistry that transforms metal into music.

The Foundation: Understanding Cymbal Alloys

The journey from raw materials to finished cymbal begins with bronze alloy selection, the most critical factor determining a cymbal’s fundamental character. Different alloy compositions create distinct tonal profiles, making alloy knowledge essential for producing cymbals that meet specific musical requirements.

B20 Bronze: The Professional Standard

B20 bronze (80% copper, 20% tin) represents the gold standard for professional cymbal manufacturing. This alloy composition provides the optimal balance of musical complexity, durability, and tonal richness that professional musicians demand.

B20 Bronze Characteristics:

- Complex harmonic structure with rich overtone development

- Exceptional musical sensitivity responding to subtle playing dynamics

- Superior durability withstanding professional performance demands

- Traditional tonal qualities prized by classical and jazz musicians

- Optimal malleability for hand-hammering and shaping processes

Alternative Alloy Compositions

While B20 bronze dominates professional cymbal manufacturing, other alloy compositions serve specific musical and economic purposes:

B8 Bronze (92% copper, 8% tin):

- Brighter, more focused tone with less complex harmonics

- Cost-effective production making quality cymbals more accessible

- Consistent tonal characteristics across production runs

- Excellent for rock and pop applications requiring cutting power

Brass Alloys (Various Compositions):

- Entry-level cymbal production for student and amateur markets

- Distinctive tonal character different from traditional bronze

- Enhanced durability in some applications

- Specialized effects in contemporary music production

Raw Material Preparation and Quality Control

The cymbal manufacturing process begins long before the first hammer strike. Raw material preparation involves rigorous quality control procedures ensuring that only premium bronze meets our manufacturing standards.

Bronze Ingot Inspection and Testing:

- Chemical composition analysis verifying precise alloy percentages

- Physical property testing confirming hardness and malleability characteristics

- Visual inspection identifying potential defects or impurities

- Documentation protocols maintaining traceability throughout production

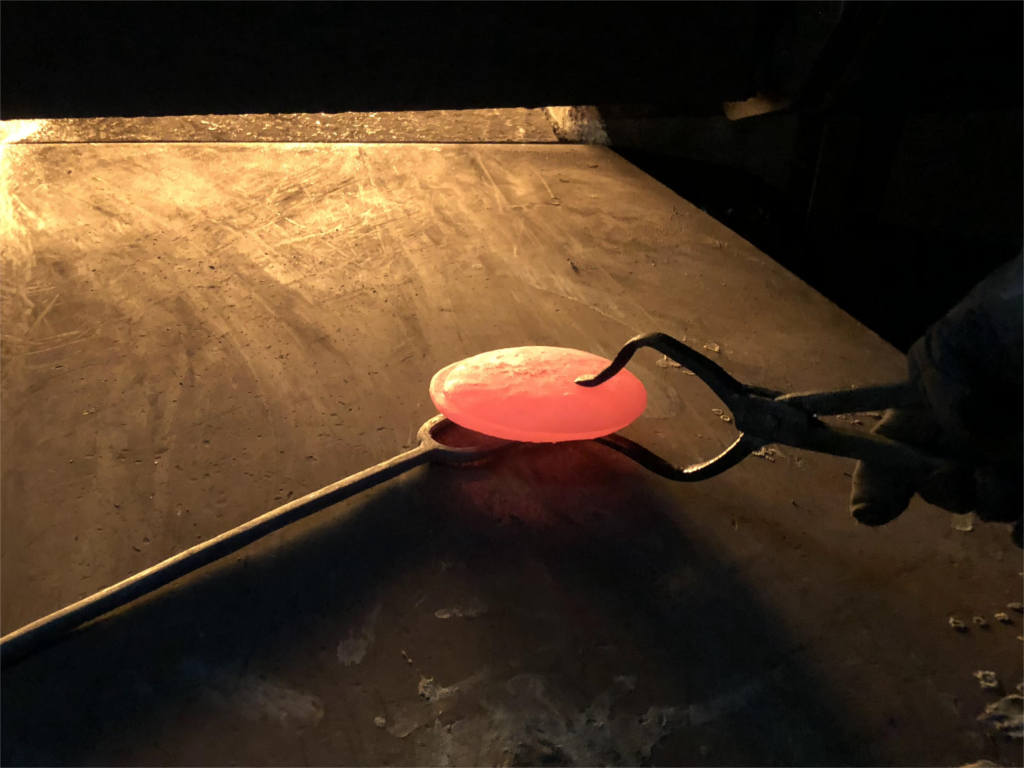

Melting and Casting Processes:

- Controlled melting temperatures optimizing alloy homogeneity

- Precise casting techniques creating uniform blank thickness

- Cooling rate management affecting bronze crystalline structure

- Initial quality assessment before proceeding to shaping stages

The Art of Cymbal Shaping: From Blanks to Bowls

Transforming flat bronze blanks into cymbal shapes requires sophisticated machinery and decades of manufacturing expertise. This critical stage establishes the cymbal’s basic proportions and structural integrity.

Hydraulic Pressing Operations:

- Progressive forming stages gradually creating the cymbal bowl shape

- Precision tooling ensuring consistent diameter and profile specifications

- Pressure control systems preventing stress concentration and cracking

- Quality monitoring at each forming stage

Traditional Spinning Techniques:

- Hand-guided spinning for premium cymbal lines

- Artisan skill application creating subtle variations in thickness and profile

- Real-time adjustment capability responding to individual bronze characteristics

- Enhanced tonal complexity resulting from traditional forming methods

The Heart of Cymbal Character: Hammering Processes

Cymbal hammering represents the most crucial stage in determining a cymbal’s ultimate tonal character. Whether performed by skilled artisans or precision machinery, hammering creates the surface texture and tension variations that generate complex harmonic content.

Hand-Hammering: Traditional Artistry

Hand-hammering remains the pinnacle of cymbal craftsmanship, requiring years of training and exceptional skill to master. Master craftsmen use traditional hammers and anvils to create the irregular surface patterns that characterize premium cymbals.

Hand-Hammering Advantages:

- Unique tonal character in every cymbal

- Complex surface texture creating rich harmonic interactions

- Artisan creativity allowing for subtle musical adjustments

- Traditional authenticity honoring centuries-old craftsmanship

- Premium market positioning reflecting superior manufacturing quality

Hand-Hammering Techniques:

- Radial pattern development from center to edge

- Varying hammer pressure creating thickness gradations

- Surface texture control affecting stick response and tonal quality

- Stress relief hammering preventing cracking and premature failure

Machine Hammering: Precision and Consistency

Machine hammering utilizes computer-controlled equipment to create consistent surface patterns while maintaining high production efficiency. Modern hammering machines can replicate traditional patterns while ensuring quality consistency across production runs.

Machine Hammering Benefits:

- Consistent quality standards across all production cymbals

- Precise pattern replication maintaining design specifications

- Efficient production rates meeting market demand requirements

- Cost-effective manufacturing making quality cymbals more accessible

- Reliable performance characteristics supporting professional applications

Lathing: Sculpting the Sound

Cymbal lathing involves carefully removing bronze material from specific areas of the cymbal surface, creating the concentric grooves that significantly affect tonal character. Lathing patterns influence everything from sustain length to frequency response.

Traditional Lathing Techniques:

- Hand-guided lathe operation allowing for artistic interpretation

- Variable groove spacing creating unique tonal characteristics

- Selective area lathing emphasizing specific frequency ranges

- Master craftsman control ensuring optimal musical results

Modern Precision Lathing:

- Computer-controlled patterns ensuring consistent groove specifications

- Programmable depth variations creating specific tonal profiles

- Quality monitoring systems maintaining dimensional accuracy

- Efficient production processes supporting various cymbal lines

Lathing Pattern Effects:

- Wide lathing: Brighter tone with enhanced overtones

- Narrow lathing: Darker, more complex harmonic content

- Unlathed areas: Creating tonal contrast and complexity

- Partial lathing: Combining different characteristics within one cymbal

Heat Treatment and Stress Relief

Heat treatment processes play a crucial role in optimizing cymbal performance characteristics. Controlled heating and cooling cycles relieve manufacturing stresses while enhancing the bronze’s musical properties.

Annealing Processes:

- Controlled temperature cycles optimizing bronze crystalline structure

- Stress relief procedures preventing premature cracking and failure

- Tonal enhancement through metallurgical optimization

- Durability improvement extending cymbal service life

Quality Control During Heat Treatment:

- Temperature monitoring ensuring optimal processing conditions

- Time cycle control achieving consistent metallurgical results

- Post-treatment inspection verifying proper stress relief

- Tonal evaluation confirming enhanced musical characteristics

Quality Assurance and Testing Protocols

Every cymbal undergoes comprehensive quality assurance testing before leaving our manufacturing facility. These protocols ensure that each instrument meets our rigorous performance standards and customer expectations.

Physical Inspection Procedures:

- Dimensional verification confirming diameter, thickness, and weight specifications

- Surface quality assessment identifying any manufacturing defects

- Structural integrity testing ensuring durability and reliability

- Visual appearance evaluation maintaining aesthetic standards

Acoustic Testing and Evaluation:

- Tonal characteristic analysis using specialized acoustic equipment

- Dynamic response testing across the full volume range

- Harmonic content evaluation ensuring appropriate overtone balance

- Musical playability assessment by qualified percussion specialists

Performance Validation:

- Professional musician testing providing real-world performance feedback

- Long-term durability studies confirming extended service life

- Comparative analysis maintaining competitive performance standards

- Continuous improvement protocols enhancing manufacturing processes

Environmental Considerations in Manufacturing

Modern cymbal manufacturing incorporates sustainable practices and environmental responsibility throughout the production process. We’re committed to minimizing environmental impact while maintaining the highest quality standards.

Sustainable Manufacturing Practices:

- Bronze recycling programs minimizing raw material waste

- Energy-efficient processes reducing carbon footprint

- Waste reduction initiatives optimizing material utilization

- Environmental compliance exceeding regulatory requirements

Worker Safety and Health:

- Comprehensive safety protocols protecting manufacturing personnel

- Advanced ventilation systems maintaining healthy work environments

- Personal protective equipment ensuring worker safety

- Continuous training programs promoting safety awareness

Innovation in Traditional Craftsmanship

While honoring traditional cymbal-making techniques, we continuously explore manufacturing innovations that enhance quality, consistency, and efficiency without compromising musical integrity.

Technology Integration:

- Computer-aided design optimizing cymbal profiles and characteristics

- Advanced metallurgy improving alloy performance and consistency

- Precision measurement systems ensuring dimensional accuracy

- Quality tracking software maintaining comprehensive production records

Research and Development:

- New alloy exploration developing enhanced tonal characteristics

- Process optimization improving efficiency and quality

- Acoustic research understanding the science behind cymbal sound

- Musician feedback integration incorporating performer insights into design

The Final Touch: Finishing and Presentation

The final finishing stages transform functional cymbals into beautiful musical instruments ready for professional performance. These processes enhance both aesthetic appeal and playing characteristics.

Surface Finishing Options:

- Traditional bronze patina highlighting natural beauty

- Brilliant finishing creating mirror-like surfaces

- Aged treatments replicating vintage cymbal characteristics

- Custom finishing meeting specific customer requirements

Quality Final Inspection:

- Complete visual examination ensuring flawless appearance

- Final acoustic verification confirming tonal specifications

- Packaging preparation protecting cymbals during shipping

- Documentation completion providing authenticity certificates

Conclusion: The Marriage of Art and Science

Cymbal manufacturing represents a unique fusion of traditional artistry and modern precision manufacturing. From the careful selection of premium bronze alloys to the final quality inspection, every step in our manufacturing process contributes to creating instruments that inspire musical creativity and enhance performance quality.

Our commitment to manufacturing excellence ensures that musicians worldwide have access to cymbals that honor traditional craftsmanship while meeting contemporary performance demands. The transformation from raw bronze to finished cymbal requires not only technical expertise but also deep understanding of musical requirements and acoustic principles.

Whether destined for intimate jazz clubs, concert halls, or recording studios, each cymbal we craft carries the dedication and expertise of skilled artisans committed to supporting musical expression. The journey from raw materials to sound represents more than manufacturing—it’s the creation of musical possibilities that will inspire performers and audiences for years to come.

The future of cymbal manufacturing lies in balancing respect for traditional techniques with embrace of beneficial innovations. As we continue to refine our processes and explore new possibilities, our fundamental commitment remains unchanged: creating cymbals that serve as faithful partners in musical expression and artistic achievement.