| Material | Silicone |

|---|---|

| Color | Red or Blue |

| Surface | Smooth |

$14.50

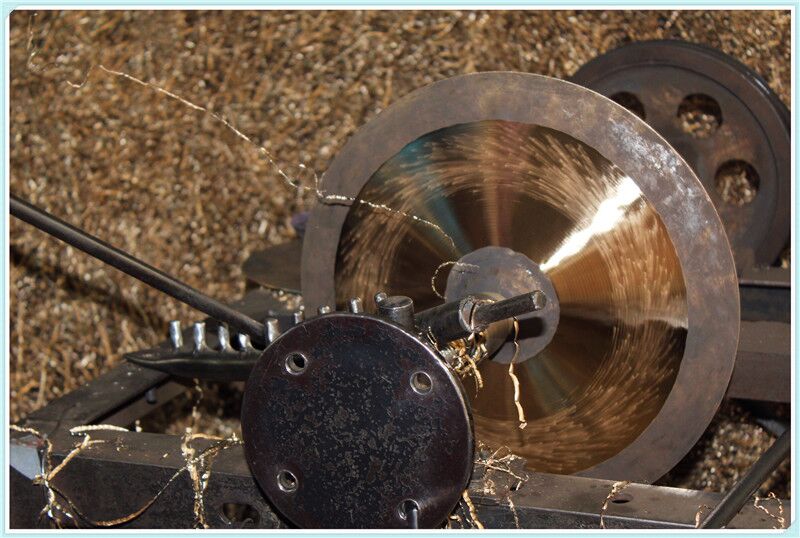

Our Double Flumie Gong Friction Mallets embody our commitment to providing high-quality accessories that enhance your musical experiences. Each mallet is expertly crafted to ensure durability and a balanced response, making it an essential tool for an immersive gong-playing experience. Suitable for all players, from beginners to professionals, the Double Flumie mallets feature a robust structure and a comfortable grip, allowing for optimal control and a wide range of tones and harmonics from your gong.Whether your musical piece demands a dramatic crescendo or a subtle, lingering note, our Double Flumie Gong Friction Mallets unlock your gong’s sonic possibilities. Aesthetically, these mallets are distinctive, with a design inspired by the graceful form of nature. They not only provide comfort but also add elegance to your musical toolkit, showcasing a well-crafted silhouette and smooth, polished finish that reflect fine craftsmanship.We understand the importance of personalization, which is why we offer customization options for our Double Flumie Gong Friction Mallets. Whether you desire a specific weight, unique grip style, or personalized engraving, you can tailor this essential tool to meet your individual needs and preferences.Investing in our Double Flumie Gong Friction Mallets is more than just acquiring a musical accessory; it’s about enhancing your musical expression, adding an aesthetic touch to your setup, and obtaining a lasting piece of craftsmanship. Dive deep into the richness of your gong’s sound with our Double Flumie Gong Friction Mallets and let them symbolize your dedication to the exquisite art of gong playing.

Fanjia Vililage, Shuizhai Town, Zhangqiu City, Shandong, China

We will contact you within 1 working day, please pay attention to the email